Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

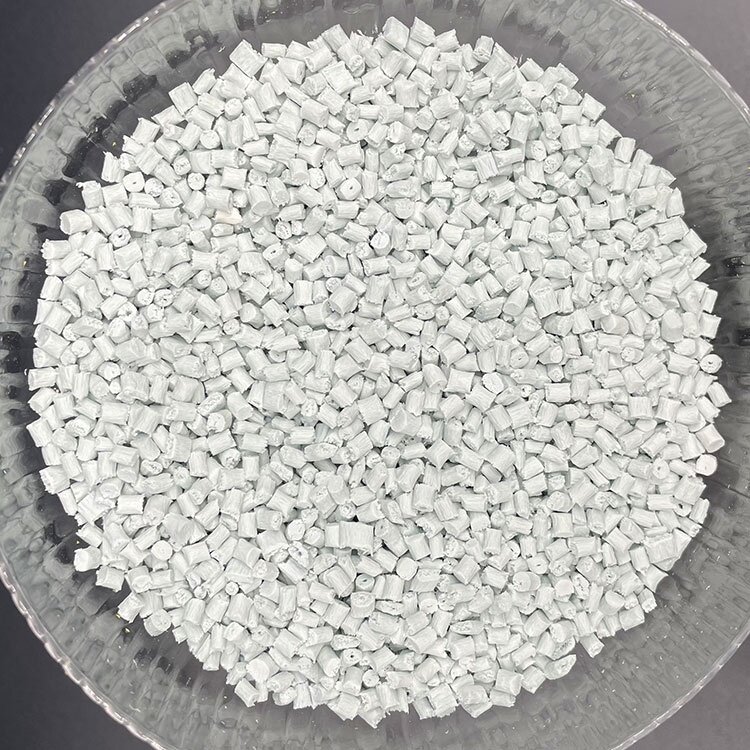

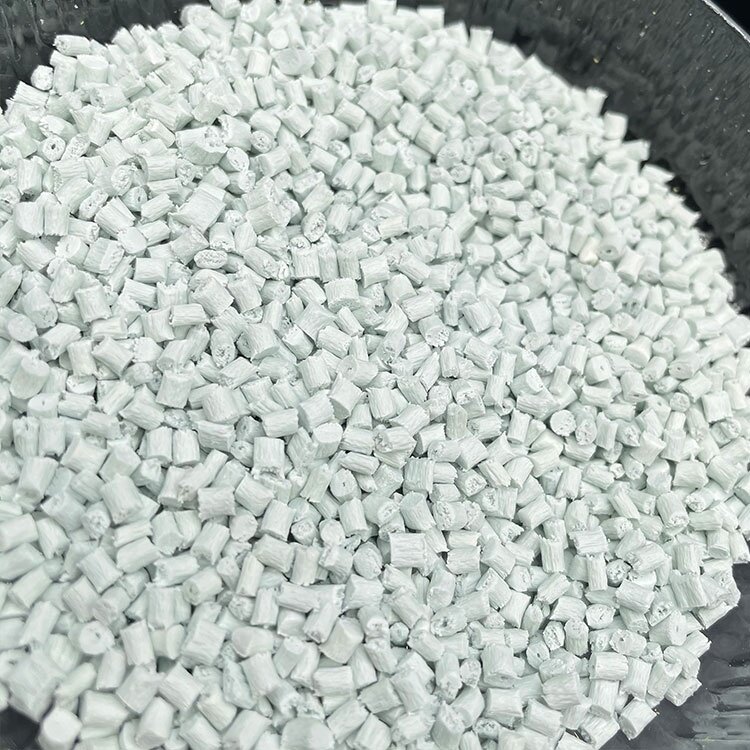

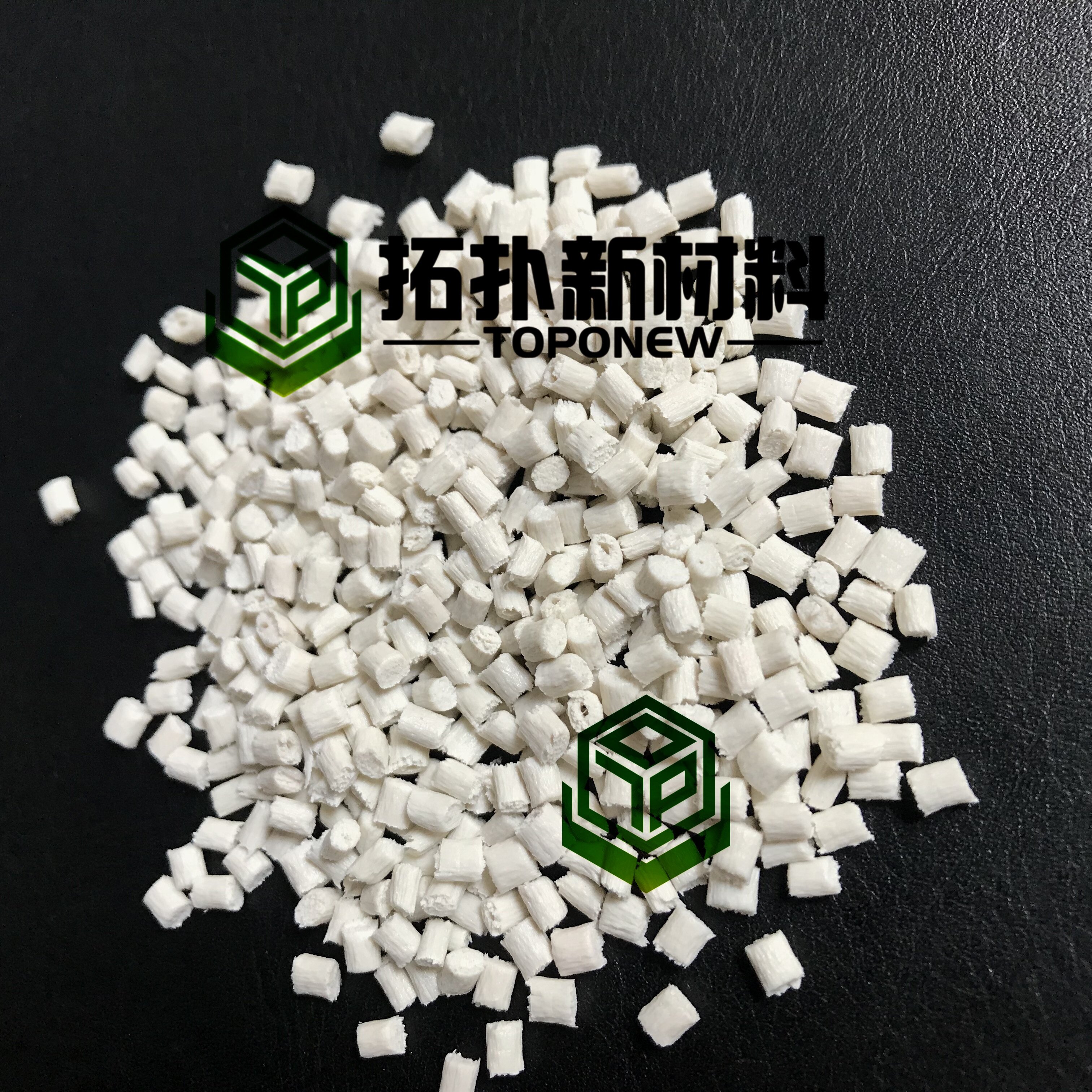

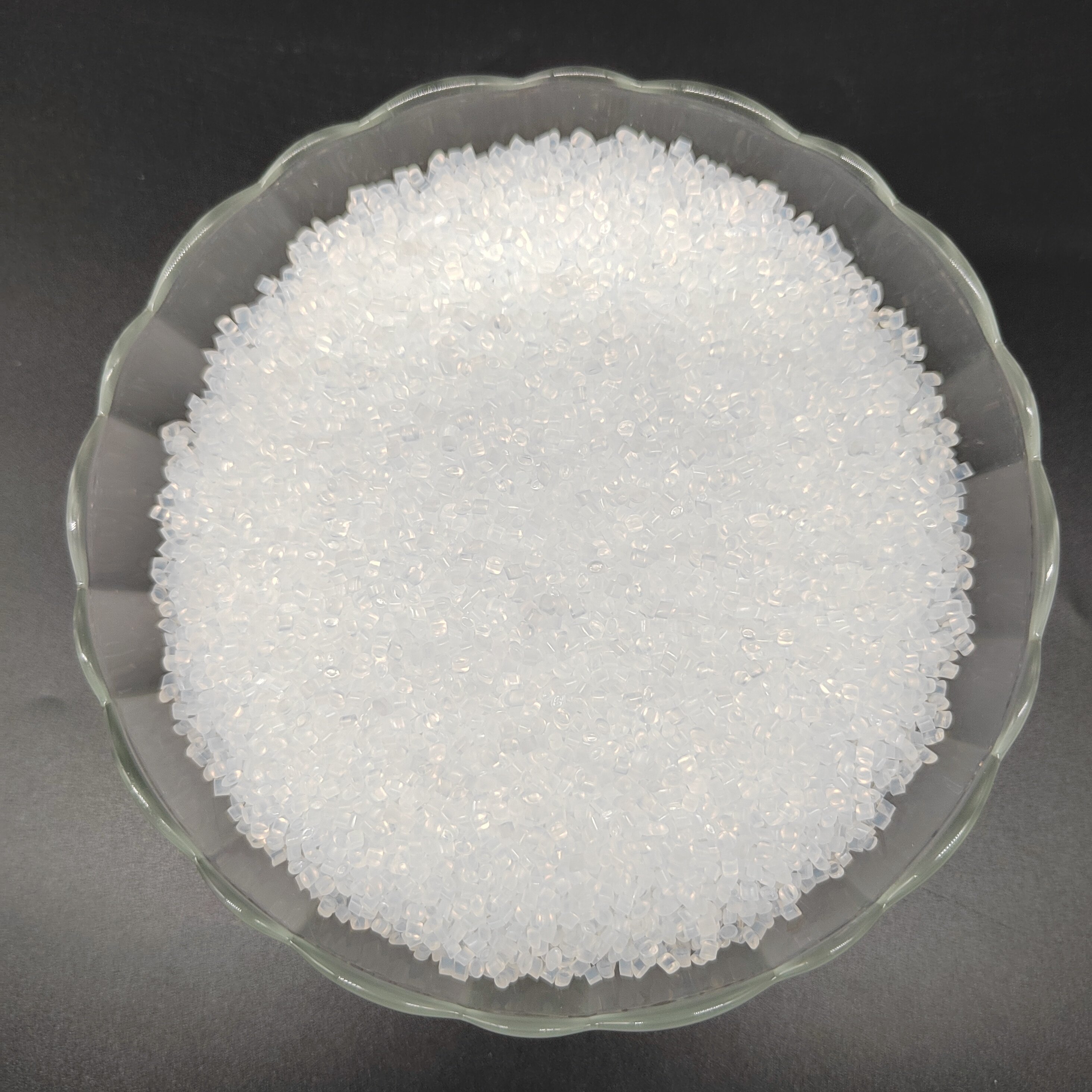

PA6 GF15 E0715

Glass Filled: 15%

Halogen added

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of PA6 GF15 E0715 Polyamide 6

Properties of PA6

PA6, also known as polyamide 6 or nylon 6, is a widely used thermoplastic material. It offers excellent mechanical strength, high rigidity, and good dimensional stability. With a melting point around 220°C, PA6 exhibits superb heat resistance, making it suitable for various applications.

Applications of PA6

The material properties of PA6 make it highly sought after in industries such as automotive, electrical engineering, consumer goods, and industrial components. Its strength and toughness make it ideal for manufacturing components that require durability and impact resistance. PA6 is commonly used for producing gears, bearings, fasteners, electrical connectors, and structural parts.

At TOPONEW, we provide high-quality PA6 resin that meets industry standards. Our nylon 6 resin boasts consistent quality and excellent melt flow properties, ensuring smooth processing during manufacturing. We prioritize delivering reliable and environmentally friendly plastic solutions to our customers.

As one of the leading nylon 6 producers, TOPONEW understands the unique requirements of different industries. Our focus on innovation and customer satisfaction sets us apart in the market, making us the preferred choice for PA6 plastic pellets.

Trust TOPONEW to provide the exceptional performance and reliability you need for your nylon 6 plastic applications. Let us help you take your projects to new heights!

Polyamide 6 (PA6) and Polypropylene (PP) are two different types of thermoplastic polymers with distinct characteristics:

-

Polymer Structure:

- PA6 (Nylon 6): PA6 is a polyamide with repeating amide bonds in its molecular structure. It has good mechanical strength, flexibility, and impact resistance.

- PP (Polypropylene): PP is a polyolefin with a simple structure composed of repeating propylene units. It is known for its low density, good chemical resistance, and stiffness.

-

Properties:

- PA6: PA6 has a higher melting point compared to PP, good resistance to wear and abrasion, and is commonly used in applications requiring toughness and impact resistance.

- PP: PP has a lower melting point than PA6, excellent chemical resistance, low moisture absorption, and is often used in applications where chemical resistance and lightweight properties are important.

-

Applications:

- PA6: Common applications of PA6 include automotive parts, textiles, industrial components, and consumer goods where toughness and durability are required.

- PP: PP is used in a wide range of applications such as food packaging, containers, automotive components, medical devices, and household goods due to its chemical resistance and lightweight nature.

In summary, PA6 (Nylon 6) and PP (Polypropylene) have different chemical structures, properties, and applications, making them suitable for different uses based on their specific characteristics.

Pourquoi polyamide 6 6 ?

Polyamide 6,6" fait référence à un type spécifique de polyamide, également connu sous le nom de nylon 6,6.

Polyamide 6,6 est fabriqué en utilisant deux monomères principaux : de l'hexaméthylènediamine (HMD) et de l'acide adipique. Lorsque ces deux monomères réagissent ensemble par un procédé de polymérisation en solution, ils forment un polymère avec une structure linéaire constituée d'unités récurrentes d'hexaméthylènediamine et d'acide adipique. Cela donne un matériau avec des propriétés telles qu'une excellente résistance mécanique, une bonne résistance chimique et une stabilité thermique élevée.

En résumé, le "6,6" dans le polyamide 6,6 fait référence aux monomères spécifiques utilisés dans sa fabrication, c'est-à-dire l'hexaméthylènediamine et l'acide adipique.

What is PA6 material standard?

PA6 is a common abbreviation for Polyamide 6, which is a type of synthetic polymer material. Polyamide 6 is a thermoplastic material that belongs to the nylon family and is known for its high strength, toughness, and chemical resistance.

In terms of standards, PA6 materials are typically governed by various industry standards and specifications depending on their intended application. Some common standards that may be relevant to PA6 materials include:

- ASTM D5989 - Standard Test Method for Determining Scratch Hardness and Scrape Adhesion of Polymeric Coatings

- ISO 1874 - Plastics. Polyamides. Determination of viscosity number

- DIN EN ISO 2580 - Plastics - Epoxy resins - Determination of hydrolyzable chlorine

- UL 94 - Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances

These standards help ensure the quality, performance, and safety of products made from PA6 materials.

What is PA6 30 GF material?

PA6 30 GF refers to Polyamide 6 with 30% Glass Fiber reinforcement. In this material, Polyamide 6 (PA6) is combined with 30% of Glass Fiber (GF) to improve its mechanical properties such as stiffness, strength, and heat resistance.

Adding glass fibers to the polyamide matrix enhances its tensile strength, impact resistance, dimensional stability, and rigidity. PA6 30 GF is commonly used in applications where high mechanical performance is required, such as automotive parts, electrical components, industrial equipment, and consumer goods.

The specific properties of PA6 30 GF can vary depending on the manufacturer, the grade of the material, and the processing conditions used. It is important to refer to the technical datasheets provided by the material supplier for detailed information on the mechanical, thermal, and other properties of PA6 30 GF.

PA6 GF60 refers to Polyamide 6 (Nylon 6) material that is reinforced with 60% Glass Fiber (GF). Similar to PA6 30 GF, PA6 GF60 is a composite material that combines Polyamide 6 with a higher percentage of glass fibers to enhance its mechanical properties.

PA6 GF60 offers even greater strength, stiffness, and heat resistance compared to PA6 with lower glass fiber content. This type of material is often used in applications that require superior mechanical performance, such as structural components in automotive engineering, industrial machinery, and electrical parts.

The addition of 60% glass fibers improves the tensile strength, impact resistance, dimensional stability, and rigidity of the Polyamide 6 matrix. As with any composite material, the specific properties of PA6 GF60 can vary based on the manufacturer, grade, and processing parameters used.

When utilizing PA6 GF60, it's essential to refer to the technical data provided by the material supplier to ensure that the material meets the specific requirements of the intended application.

Download

-

PA6GF15.pdf

Download PA6GF15.pdf